As the world becomes increasingly focused on sustainability and responsible business practices, companies are facing growing pressure to meet compliance standards for reverse logistics. In this definitive guide, we’ll explore the key requirements that businesses must navigate when implementing a successful reverse logistics program.

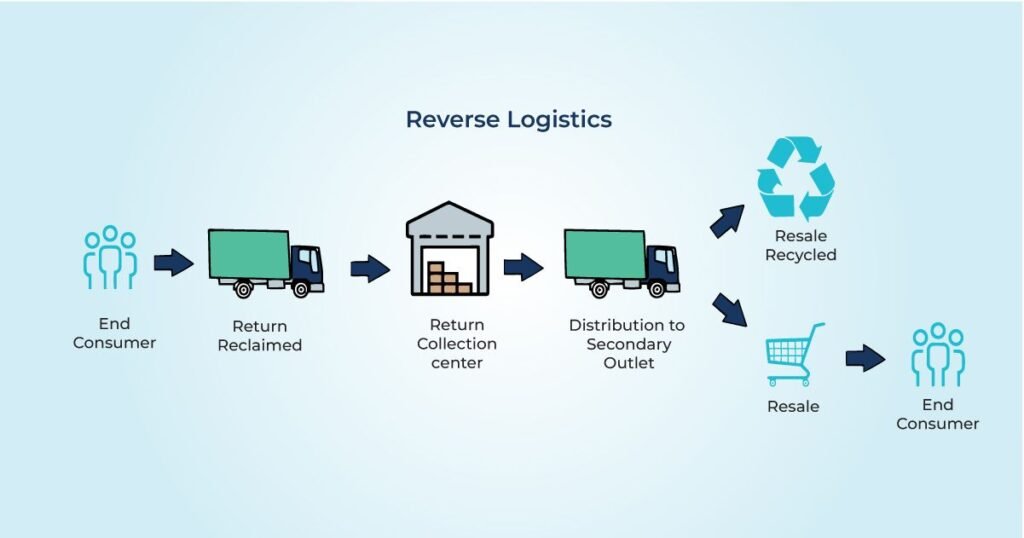

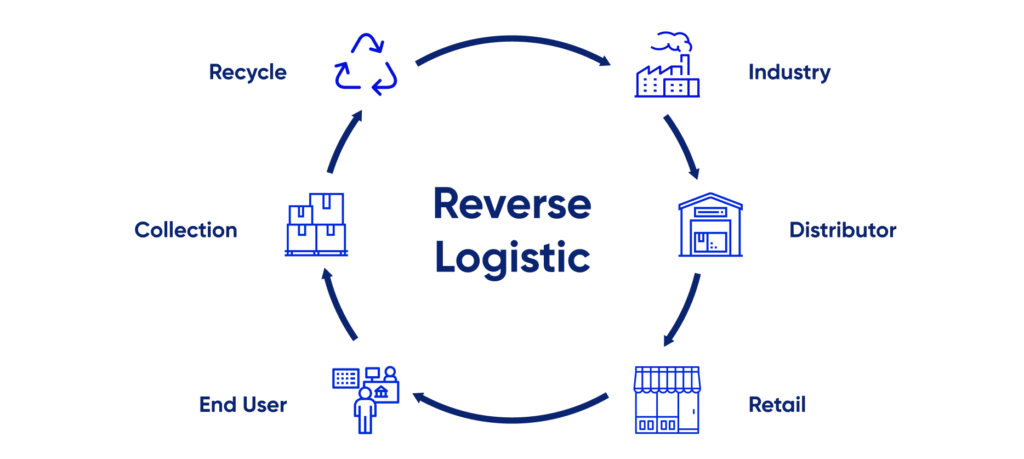

Reverse logistics refers to the processes involved in managing the flow of products, materials, and information in the opposite direction of traditional supply chain operations. It encompasses activities such as returns management, product recalls, and recycling initiatives.

Meeting compliance standards in reverse logistics involves not only adhering to legal and regulatory frameworks but also adopting best practices that minimize waste, reduce environmental impact, and maximize efficiency. This includes properly documenting and tracking returned products, ensuring proper disposal or refurbishment, and implementing sustainable packaging solutions.

By understanding the complex landscape of reverse logistics requirements, businesses can not only align with regulatory expectations but also unlock valuable opportunities for cost savings, customer satisfaction, and brand reputation. Join us as we dive into the world of reverse logistics compliance standards and discover how to navigate them successfully.

What is reverse logistics?

Reverse logistics refers to the processes involved in handling products, materials, and information in the reverse supply chain. Unlike traditional supply chain operations that focus on delivering products to customers, reverse logistics deals with the movement of goods from the customer back to the manufacturer or retailer. It encompasses various activities, including product returns, repairs, refurbishment, recycling, and proper disposal.

The importance of reverse logistics has grown significantly in recent years due to increasing customer expectations, sustainability concerns, and regulatory requirements. By effectively managing reverse logistics, businesses can reduce costs, improve customer satisfaction, and enhance their overall brand reputation.

Compliance Standards in Reverse Logistics:

Reverse logistics is a crucial part of supply chain management that involves the movement of goods from the customer back to the seller or manufacturer. It includes activities like returns management, refurbishment, recycling, and disposal. Here are some key points to consider when aiming to meet compliance standards in reverse logistics:

1. Authorized Hazardous Materials: Hazardous materials may be offered for transport and transported in highway transportation when they meet the definition of reverse logistics. However, hazardous materials that meet the definition of a hazardous waste are not permitted to be offered for transport or transported under this section.

2. Transportation: When offered for transport or transported by non-private carrier, hazardous materials must be both authorized for limited quantity provisions as well as explicitly authorized for reverse logistics transportation under their applicable limited quantities section.

3. Private Carrier: When offered for transport or transported by private carrier, hazardous materials are authorized under certain limitations.

4. Regulations: Ensure you are aware of and comply with all relevant regulations, such as the Resource Conservation and Recovery Act (RCRA) regulations.

5. Value Regain: The goal of reverse logistics is to regain value from the product or dispose of it. This process can return products one step back in the chain or to the original supplier.

6. Customer Loyalty: Savvy companies use reverse logistics to build customer loyalty and repeat business and to minimize losses related to returns.

Remember, the specifics of reverse logistics can vary greatly depending on the industry and the nature of the goods involved. Always consult with a logistics professional or legal advisor to ensure you are meeting all compliance standards. If you have any more questions, feel free to ask!

Importance of meeting compliance standards in reverse logistics

Meeting compliance standards in reverse logistics is crucial for several reasons. Firstly, it ensures that businesses comply with legal and regulatory frameworks established by authorities. Failure to meet these standards can result in penalties, legal issues, and damage to a company’s reputation.

Secondly, compliance standards in reverse logistics help businesses adopt best practices that minimize waste, reduce environmental impact, and maximize efficiency. By following these standards, companies can reduce the amount of returned products that end up in landfills, improve recycling and refurbishment processes, and optimize their overall reverse logistics operations.

Lastly, meeting compliance standards in reverse logistics allows businesses to enhance customer satisfaction and brand reputation. Customers value companies that prioritize sustainability and responsible practices. By effectively managing reverse logistics and meeting compliance standards, businesses can build trust, loyalty, and positive brand associations with their customers.

Understanding compliance standards in reverse logistics

To meet compliance standards in reverse logistics, businesses must have a thorough understanding of the applicable legal and regulatory frameworks. Compliance requirements vary by country, region, and industry, making it essential for businesses to stay up-to-date with the latest regulations in their specific domain.

Some common compliance standards in reverse logistics include:

Key compliance standards

Compliance standards in reverse logistics can vary depending on the industry and geographical location. Here are some key compliance standards that businesses should be aware of:

Tools and technologies to facilitate compliance in reverse logistics

Implementing the right tools and technologies can greatly facilitate compliance in reverse logistics. Here are some examples:

Tips for meeting compliance standards in reverse logistics

Meeting compliance standards in reverse logistics can be challenging, but with the right approach, businesses can navigate these requirements successfully. Here are some tips to consider:

The role of data management in ensuring compliance

Effective data management plays a crucial role in meeting compliance standards in reverse logistics. Proper collection, analysis, and utilization of data enable businesses to make informed decisions, identify compliance gaps, and optimize their reverse logistics operations. Data management also supports accurate documentation, tracking, and reporting, which are essential for compliance with regulatory requirements.

Businesses should invest in robust data management systems and processes to ensure accurate and timely access to relevant information. By leveraging data, companies can improve compliance, enhance operational efficiency, and drive continuous improvement in reverse logistics.

Training and education for logistics compliance

To meet compliance standards in reverse logistics, businesses should invest in training and education for their employees. This helps ensure that everyone involved in reverse logistics operations understands the compliance requirements, follows proper procedures, and stays updated with changes in regulations.

Training programs can cover topics such as documentation and tracking, proper disposal and refurbishment practices, sustainable packaging solutions, and the use of compliance management tools and technologies. By equipping employees with the necessary knowledge and skills, businesses can enhance compliance, reduce errors, and optimize their reverse logistics processes.

Outsourcing logistics compliance services

For businesses that lack the expertise or resources to manage reverse logistics compliance internally, outsourcing compliance services can be a viable option. Reverse logistics service providers specializing in compliance can offer expertise, industry knowledge, and tailored solutions to meet specific compliance requirements. Outsourcing compliance services allows businesses to focus on their core competencies while ensuring compliance in reverse logistics.

Meeting compliance standards in reverse logistics is a multifaceted challenge that requires businesses to navigate legal requirements, adopt best practices, and leverage technology effectively. By understanding and meeting compliance standards, companies can not only avoid legal consequences but also unlock opportunities for cost savings, customer satisfaction, and brand reputation. By implementing the tips and strategies outlined in this guide, businesses can successfully navigate the complex landscape of reverse logistics compliance and build a sustainable and compliant program.

Quick Takeaways:

1. Reverse logistics refers to the processes involved in managing the flow of products, materials, and information in the opposite direction of traditional supply chain operations. It includes activities such as returns management, product recalls, and recycling initiatives.

2. Meeting compliance standards in reverse logistics involves adhering to legal and regulatory frameworks, as well as adopting best practices to minimize waste, reduce environmental impact, and maximize efficiency.

3. Compliance standards in reverse logistics may include requirements for handling hazardous materials, transportation regulations, and adherence to specific regulations like the Resource Conservation and Recovery Act (RCRA).

4. The goal of reverse logistics is to regain value from products or dispose of them properly. It can involve returning products one step back in the chain or to the original supplier.

5. Compliance with reverse logistics standards can help businesses reduce costs, improve customer satisfaction, and enhance brand reputation.

6. Compliance requirements in reverse logistics can vary by industry and geographical location, so businesses should stay up-to-date with the latest regulations applicable to their specific domain.

7. Implementing tools and technologies can facilitate compliance in reverse logistics, including systems for data management, documentation, tracking, and reporting.

8. Training and education for employees are important for ensuring compliance in reverse logistics. Employees should be familiar with compliance requirements, proper procedures, and changes in regulations.

9. Outsourcing reverse logistics compliance services can be an option for businesses that lack the internal expertise or resources to manage compliance effectively. Reverse logistics service providers can offer specialized expertise and tailored solutions.

10. Effective data management plays a crucial role in meeting compliance standards in reverse logistics. Proper collection, analysis, and utilization of data enable businesses to make informed decisions, identify compliance gaps, and optimize their operations.

By following these key takeaways, businesses can navigate the complex landscape of logistics compliance and build a sustainable and compliant reverse logistics program.

check out our previous blog post by clicking here: